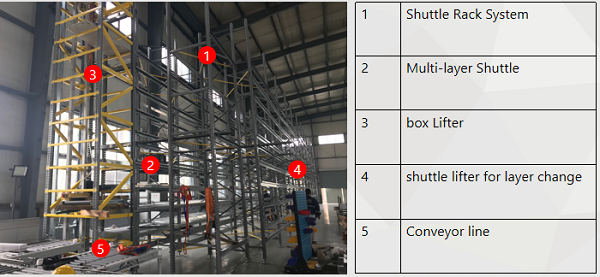

Multi-layer Shuttle Rack System

Multi-level mini-load shuttle system (Multi layer Speedshuttle) from Maxrac (Member of Speedlog) is the solution for efficient storage and picking of trays, containers and cartons in a fully automated warehouses. It consists of Rack System, Multi-level Shuttle, Elevator, Conveyor Line and other equipment, combined with WCS/WMS to form into a fully automated storage system.

It's suitable for storage of light duty units in cartons and bins with multiple SKU, large volume that needs fast picking and sorting, widely used in e-commerce, FMCG, third-party logistics and other industries.

Multi-layer shuttle is automatic equipment running on the rail which can automatically picking goods. It's mainly composed of the shuttle cart and telescopic fork.

Classified by running direction:

2-way shuttle

4-way shutlle

Classified by access depth:

Single-depth shuttle

Double-depth shuttle

Comparing Multi-layer Shuttle System with Mezzanine and Miniload

| Solutions | Mezzanine | Mini Load AS/RS | Multi-layer Shuttle System |

Pics |  |  |  |

| Storage Capacity | High | High | High |

| Automation | Non automatic | Full automatic | Full automatic |

| Efficiency | Low | Mid | High |

Dependence of single equipment | No(man power) | High | Low |

| Labor Cost | High | Low | Low |

Specification of Multy-layer Speedshuttle:

Multy-layer Shuttle Specification | |

Load | 0-30KG |

Running Speed | 4m/s |

Running Accelerated Speed | 2m/S2 |

PositionaI Accuracy | +/-1mm |

Power Supply | lithium battery |

Control Mode | PLC |

Communication Mode | wireless communication |

Noise | DB<70 |

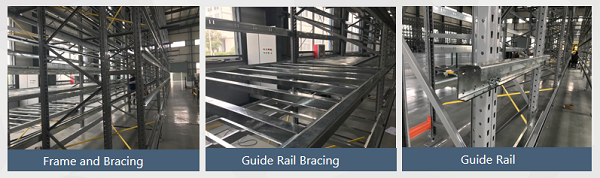

Rack for multi-layer shuttle consists of frame, horizonal bracing, guide rail, rail bracing and adjustable baseplate.

Shuttle is running on the guide rail and brings cargo to designated location on rail bracing. which requires high manufacturing

and installation precision on the racking

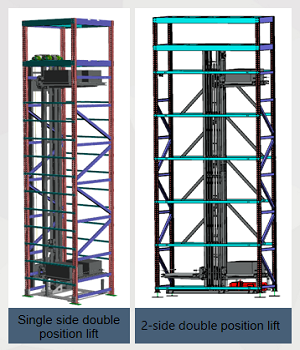

Box Lifter

Mini-load lift is used to lift the bins from the lowest level to the corresponding receiving layer required by the system.

The shuttle cart move to the entrance of lane to pick or place the cargo from the lifter

Two Type of Mini-load lift:

a. Single side double position lift

b. 2-side double position lift

Loading: 0-60KG

Max lifting height: 24m

Min conveying height: 600mm

Lifting speed: 3m/s

Lifting acceleration: 2m/S2

PositionaI Accuracy: +/-2mm

Power Supply: motor drive

Control Mode: PLC

Communication Mode: wireless communication

Noise: DB<70

When the system efficiency is not high, it's not necessary to have a shuttle on each layer.

Then it needs a lifter to help shuttle cart to change layers.

Load: 0-300KG

Max lifting height: 24m

Min conveying height: 600mm

Lifting speed: 40m/min

Lifting acceleration: 0.6 m/S2

PositionaI Accuracy: +/-2mm

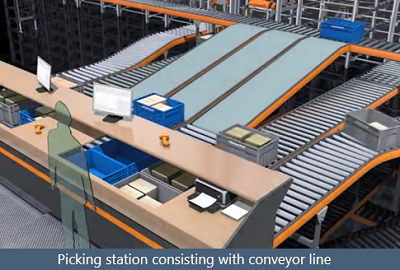

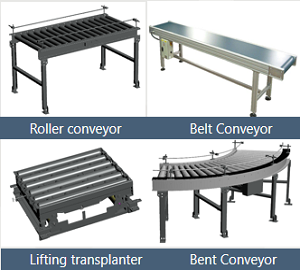

Conveyor Line

At the front end of the multi-layer shuttle system, it always has a large number of conveyor lines that combine into inbound&outbound and picking area, mainly including roller conveyor and belt conveyor lines.

3D simulation

3D simulation  Cart installation

Cart installation  Side view

Side view  Box bin

Box bin