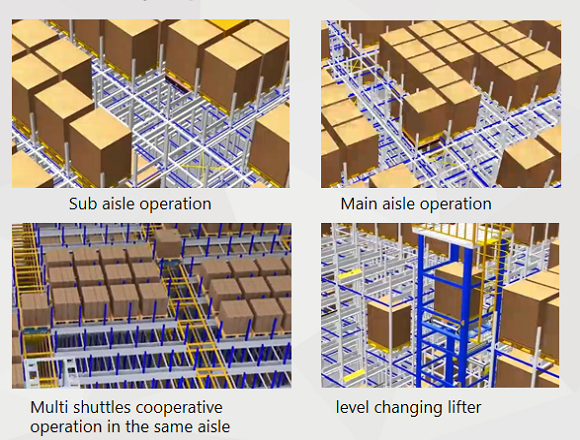

Pallet shuttle system (4 way speedshuttle) is automated high-density storage and retrieval system for the handling of palletized goods. It's an optimal solution for the storage of goods with mass quantity and small SKU, widely used in the industry of Food&beverage, chemical, third party logistics etc. It's an updated version of standard radio shuttle system. The shuttle is able to move in 4 directions on the storage lanes and main lanes. In this way the shuttle can change lanes without operation of forklift, greatly save labor cost and improve warehousing efficiency.

Four way pallet shuttle function introduction

Manual function

Automatic cargo in and out

Automatic cargo transfer

Inventory technology

Online charging function

Low power alarm function

Remote control function

telecontrol function

System monitoring

Emergency stop function

Log upload function

Four way pallet shuttle system usually consists of Racking System, Radio Shuttle, Elevator, Conveyor and WMS/WCS system.

Conveyor line is placed in front of racking system for picking and receiving of pallets. Elevator will transport radio shuttle and pallets from ground to different layers. With instruction of WMS/WCS system, radio shuttle is able to automatically pick and deliver pallets to appointed position inside racks, which could realize automatic storage and retrieval of goods in warehouse.

The pallet what used for the four-way shuttle system, must be passed by speedlog test, As shown below:

Greatly increase storage capacity, which is 3-4 times large than traditional racking system.

Cost effective and time-saving, reduce land and labor cost

Fully automatic, low level of risks or damage to the equipment and operator.

Self-designed WMS/WCS system to well match shuttle system.

Available to meet various storage capacity demand with adjustment of shuttle quantity.

1. Independent research and development, own intellectual property. advantages on After sale service.

2. Whole plate lifting design can prevent small particles or oil stains from entering the car body and affecting service life.

3. With own professional software team, can connect our system with customers existing automation equipments or WMS, which can help upgrade the warehouse from semi automation to full automation.

4. With rich export experience, we can support customers to deploy overseas markets.

| Solutions & Costs | Conventional beams type racking | Stack crane ASRS | Four-way pallet shuttle system |

Layout |

|

|

|

Storage Cap. | Low | Middle | High |

Automatic | Non automatic | Full Automatic | Full Automatic |

Efficiency | Low | High | Middle |

Dependence of single equipment | No(man power) | High | Low |

Labor cost | High | Low | Low |

The pallet shuttle can carry hundreds of kilograms to one ton of pallet goods. The pallet four-way shuttle is an improvement in the structure of the two-way shuttle. The pallet two-way shuttle can realize "first-in, first-out" when picking up goods. Or the "first in, last out" model, which is mostly used in industries with large quantities and few varieties. However, with the continuous development of the market, the demand for small batches and multiple batches is increasing. At the same time, affected by factors such as land use and labor costs, enterprises have an increasingly urgent need for space utilization and dense storage. In this context, the four-way pallet shuttle that can realize intensive storage, space utilization and flexible scheduling came into being. At present, the pallet 4 way shuttle system has applications in manufacturing, cold chain and other industries. In addition, for old industrial parks and warehouses with few varieties and large quantities of goods, the pallet four-way shuttle system can also be considered to make full use of the height space of the warehouse, release more economic production capacity, and create value for customers. The specific applications are as follows:

1. A company with fewer items and more pallets.

2. Companies with high levels of loading and unloading activities.

3. Cold storage: It is very suitable for warehouses that need low temperature because it makes full use of storage space and reduces operation time. The system is more efficient when a stacker or transfer vehicle is used to install the automation system.

4. Buffer for temporary storage or order picking.

5. Seasonal product warehouse, inflow and outflow depend on the season, goods accumulate over a period of time until a large release at a specific moment, such as ice cream or toys.

6. Warehouses that need to access more items, store more pallets in depth, or increase the number of in and out movements to increase their productivity.

MAXRAC provide all shuttle solutions, send us your requirements and we will customize your rack and pallet shuttle system.

Specification of 4-way pallet shuttle

Max loading: 2.5t

Speed: 0.6-1.0m/s

Acceleration speed: 0.3m/s

Position accuracy: ±2mm

Operating temperature:0-45℃

Racking parts

1. 50mm pitch adjustable

2. Wear resistant guide rail

3. Ajustable baseplate

4. Universal shuttle rails with normal radio shuttle system

3D simulation

3D simulation  PAD digital operation

PAD digital operation  Removable battery

Removable battery  Pallet rail

Pallet rail  Pallrt rail arm

Pallrt rail arm  Export package

Export package