Automated storage and retrieval systems (also known as ASRS systems) are most commonly used in manufacturing and distribution facilities. They often replace large areas of shelving to save floor space, improve security and increase productivity. With technology and applications constantly changing, it can be a bit overwhelming to look into ASRS systems for the first time. Have no fear. We've put together a one-stop "Introduction to Automated Storage and Retrieval Systems" for you.

Automated systems allow for efficient and secure storage of items in a compact space. They also allow users to easily and quickly retrieve items when they need them. Several companies produce a variety of stand-alone automated shipment-to-man storage and retrieval systems (ASRS). These technologies handle different quantities, types and speeds of non-palletized inventory at variable speeds to accommodate different throughput needs. When considering options, keep in mind the storage density required for your facility and your throughput goals.

There are a range of alternative names for automated storage and retrieval systems, such as dynamic storage systems, high-density storage and retrieval systems, and goods-to-person picking technology.

Replenishment overload - if workers are spending as much time on replenishment as they are on picking, you're wasting time - consider automation!

Lots of travel time - if workers are wasting time traveling miles to access inventory during their shifts - consider automation!

Excessive search time - if upon arrival at the picking destination, workers must spend time visually searching for the correct item and matching the part number - consider automation!

Rising picking errors - if picking errors are on the rise, wasting money and jeopardizing your company's reputation - consider automation!

Struggling throughput - if you're struggling to keep up with order deadlines or hiring seasonal workers to meet demand - consider automation!

Damaged items - if valuable inventory is often found to be damaged and unusable - consider automation!

Misplaced inventory - if inventory is frequently misplaced or temporarily lost - consider automation!

Stolen items - if inventory is often unexplainably lost - consider automation!

Facility at maximum capacity - if your building is bursting at the seams and there is no room to grow - consider automation!

Risk of operator injury - if workers are at risk of injury - consider automation!

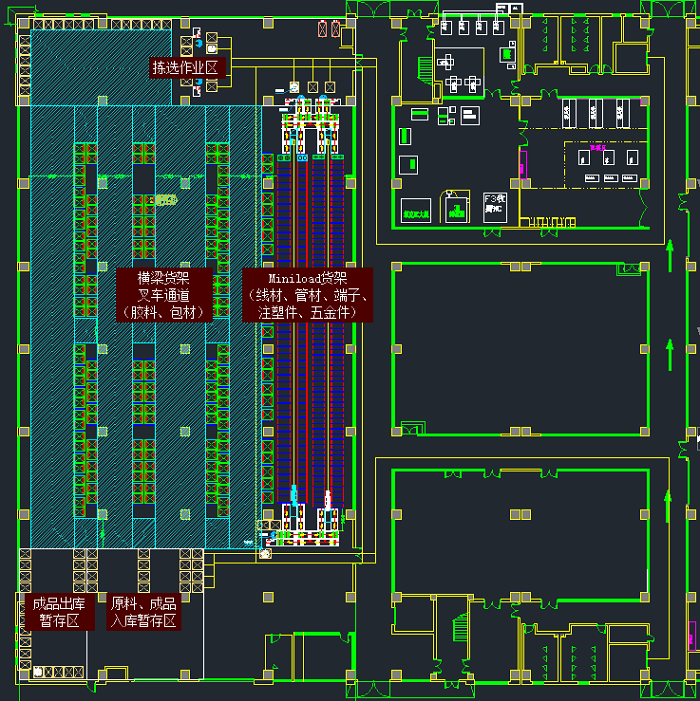

ASRS Pallet rack System Project

There are many benefits to automated storage and retrieval systems, they include.

Small footprint - ASRS technology provides highly dense storage space that can save up to 85% of the floor space occupied by shelving. Calculate the true cost of storage space

Reduced labor requirements - ASRS systems require 2/3 less labor to operate than manual shelving. Calculate the true cost of labor

Improved picking accuracy - The automated ASRS uses pick-by-light technology to direct operators to the exact location of stored items with 99.9% picking accuracy. Calculate the true cost of accuracy

Better inventory control - ASRS solutions manage inventory, so you always know what you have and more importantly - where it is.

Improved safety and ergonomics - ASRS technology creates a safe and ergonomic work environment for employees.

Please contact MAXRAC today to get help, we welcome your inquiries.