Project introduction

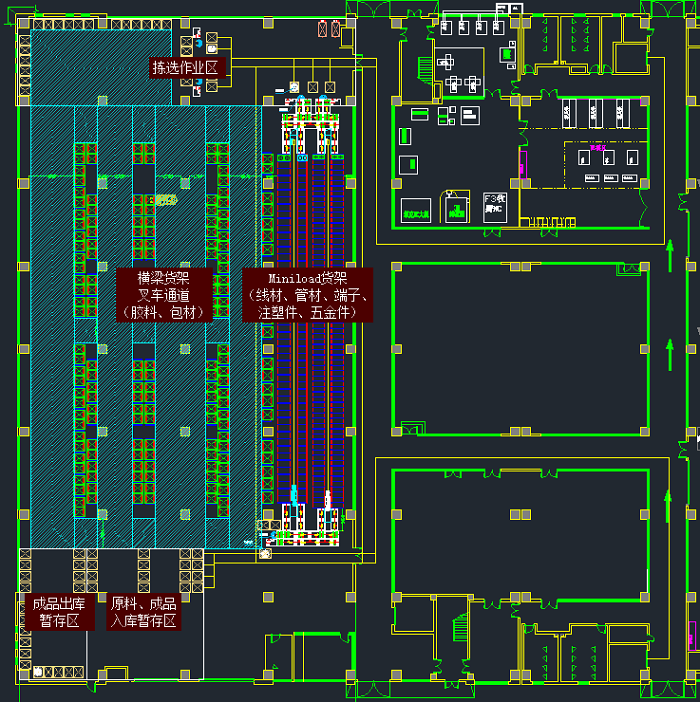

The factory covers a total area of more than 13000 square meters, of which the actual use area of direct production workshop is 11000 square meters and the R & D office area is about 2000 square meters;

Project scale

It covers an area of nearly 3000 square meters and has more than 10000 SKUs

minilord bin locations: 4640 bin locations.

Pallet locations: 546 pallet locations.

Problems in operation

The product packaging in the warehouse is irregular packaging. There are 10 kinds of products. Wire products, terminals, moulded shells, pipes, electronic components, PCB boards, plastic particles, injection parts, chemical preparations, hardware, foam cotton, valuable materials, customer supplies, etc., SKU reaches more than 10000, basically small batch and multi varieties. Looking for items depends on very experienced factory warehouse managers. It is difficult for general warehouse managers to find logistics, which is extremely inefficient and has brought great obstacles to production.

Our Solution

Inbound process

1. Stock in temporary storage of raw materials and finished products: after raw materials enter the warehouse, they are stored in the stock in area for code scanning and binding of material information; The AGV transports the finished products to the warehouse, temporarily stores them in the temporary storage area, and sends information to the system to record the location of the finished products;

2. Beam pallet shelf Warehousing: the forklift transports the pallet from the warehousing temporary storage area to the beam shelf for storage, inputs the location information in the system, binds the pallet location, and completes warehousing.

3. Miniload cargo handling: the system will prompt the pallet position, the forklift will transport the corresponding pallet to the storage station of the material box, manually transport the goods onto the conveying line, empty the turnover box, scan the code and bind

4. Automatic warehousing of material boxes: the conveying line scans the barcode on the turnover box, and the system assigns the warehouse location. The conveying line and stacker automatically store the turnover box into the corresponding location to complete warehousing.

Outbound process

1. Pallet cargo handling and picking: the forklift will transport the pallets to be picked to the picking operation area for picking; The forklift transports the pallet to the pallet picking station, manually picks the goods from the pallet, scans the bar code of the goods, and places the goods on the picking order pallet. When the picking of an order pallet is completed, after call the AGV cart.

2. Miniload shelf picking: the system issues the outbound picking task, the stacker transports the goods to the picking station for picking, manually scans the bin code, takes the goods, scans the order pallet, and places the goods on the pallet. When an order pallet is picked, call AGV

3. Bin return: the bins after picking are transported to the original storage location by conveyor line and stacker

4. Material transportation after picking: AGV transports the order tray to the production line

5. Return of pallet goods to warehouse: the selected raw material supply pallet is transported back to the four-way shuttle shelf and beam shelf by forklift for in-situ storage.

6. Cross beam pallet shelf material transportation: the forklift will take out the pallet to the designated location according to the system prompt and send it to the warehousing and warehousing temporary storage area for temporary storage

7. Pallet stock out: manually stock out the goods according to the system prompt to the specified location, and the system updates the inventory information to complete the stock out of finished products.

Result analysis

1. The storage capacity has doubled compared with the original old warehouse.

2. The original number of warehouses is more than 3000. After being installed in the intelligent warehouse, the number of warehouses is about 6000.

3. The picking efficiency is about 25% higher than the original manual efficiency.