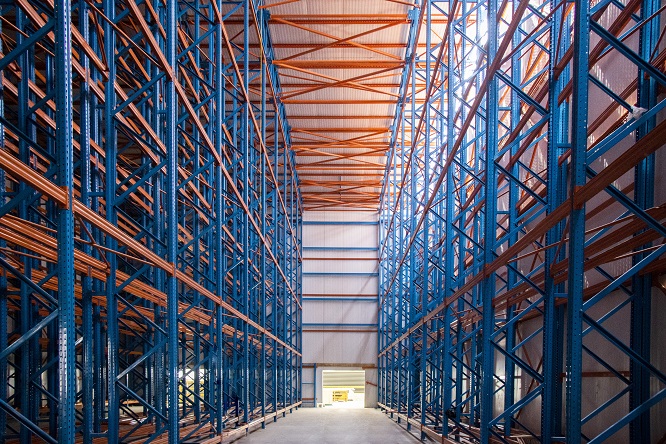

Self support racking Project in Guatemala

A self-supporting racking project involves designing and constructing a storage system where the racking itself supports the building structure, eliminating the need for a separate building framework. This type of system, also known as a rack-supported building or rack-clad warehouse, is ideal for maximizing storage space and efficiency.

Installation time: 2023

Installation location: Guatemala

Project scale: cold storage at minus 20℃, storing fresh meat food, more than 2,000 pallet spaces

5 warehouse projects have been completed, The First Phase project began in 2013

Self support racking is a collection of racks and warehouses, the main body of the warehouse is built by the rack, and the outer wall of the warehouse, the roof, and other related equipment are built on the racking, forming an overall warehouse structure. Self support racking is widely used in large distribution centers, food and beverage, tobacco, chemical, and other industries. It's a typical representative of high-density warehouse storage solution, which has high requirements for design, installation, and project management.

Shanghai Maxrac has been building self support racking projects in Guatemala every two years for eight years, demonstrating the company's technical heritage in the field of warehousing solution.

Needs Assessment: Determine storage needs and design specifications.

Site Evaluation: Assess the site for suitability and layout.

Engineering Design: Develop detailed engineering plans, including load calculations and structural analysis.

Regulatory Compliance: Obtain necessary permits and ensure compliance with local building codes.

Foundation Work: Prepare the site and lay the foundation.

Racking Installation: Erect the racking system, ensuring precise alignment and structural integrity.

Roof and Walls: Install the roof and wall panels, integrating them with the racking system.

Automation and Material Handling: Integrate automated systems and material handling equipment as needed.

Safety and Load Testing: Conduct safety inspections and load tests to ensure structural integrity.

Final Adjustments: Make any necessary adjustments and calibrations.

Training: Train staff on the operation and maintenance of the new system.

Regular Inspections: Implement a schedule for regular inspections and maintenance.

Compared with the traditional warehouse, self support racking has its special characteristics:

1. High density, high utilization rate of space and land area

2. Cost advantage under scale effect, short construction period

3. Manufacturing accuracy and construction are difficult

Previous: None

Next: fgg