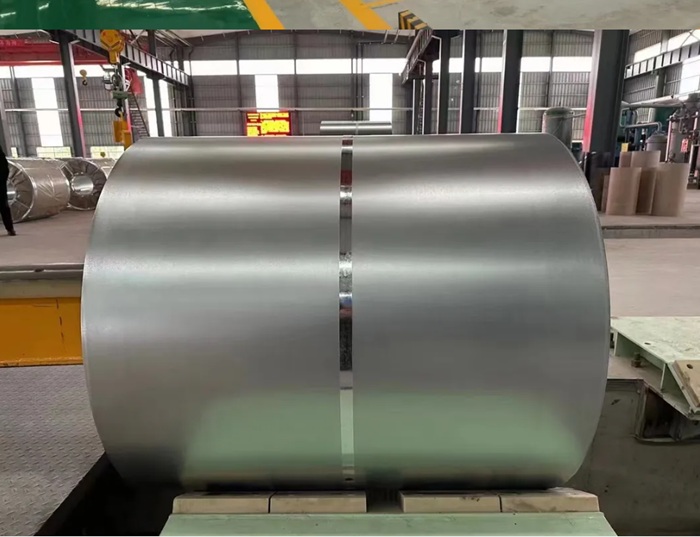

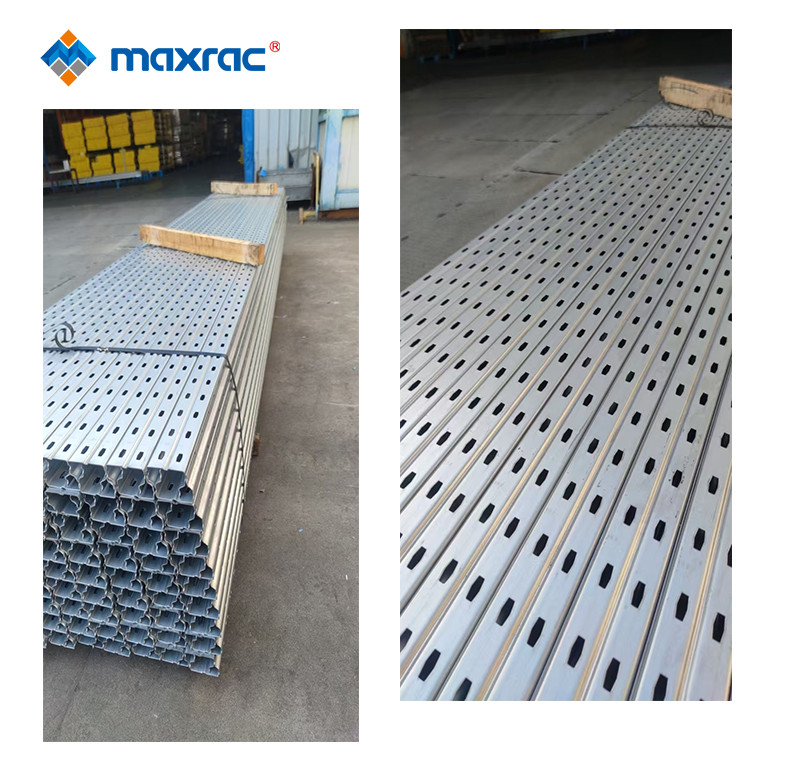

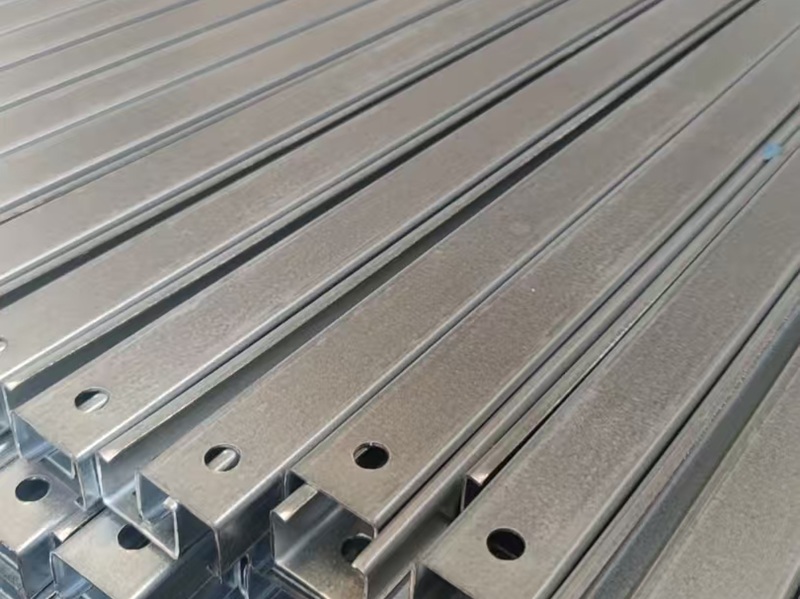

Our zam zinc-aluminum-magnesium (Zn-Al-Mg) coated racking uprights are made from high-strength steel with a Zn-Al-Mg alloy coating, offering superior corrosion resistance, high load capacity, and extended lifespan. Ideal for warehousing, industrial shelving, automated storage systems, and more, ensuring a stable and durable support structure.

✅ Exceptional Corrosion Resistance – ZAM coating provides 3-5x better rust protection than standard galvanized steel, ideal for humid or high-salt environments.

✅ High Load Capacity – Made from high-tensile cold-rolled steel, with upright thickness options of 1.5mm–3.0mm, supporting up to 5,000kg per shelf level.

✅ Longer Lifespan – Self-healing coating properties reduce rust risk, ensuring 15-20 years of service life.

✅ Lightweight Design – 10% lighter than traditional steel uprights, reducing shipping and installation costs.

✅ Eco-Friendly – Chromium-free passivation, compliant with RoHS environmental standards.

Ideal Applications

✔ Warehousing & Logistics – E-commerce fulfillment centers, cold storage, automated AS/RS systems

✔ Industrial Shelving – Heavy-duty racks, narrow-aisle racks, shuttle racks

✔ Harsh Environments – Coastal areas, high-humidity factories, chemical storage

✔ Global Export – Compliant with ISO 9001, SGS certifications

Alloy Composition: Primarily zinc (Zn), with added aluminum (Al, 1.5-11%) and magnesium (Mg, 1-3%), forming a dense ternary eutectic structure.

Self-Healing Properties: When the coating is damaged, oxides of aluminum and magnesium quickly form a protective film to prevent rust spread.

Microscopic Features:

Uniformity: More uniform than traditional zinc coatings, reducing porosity.

Adhesion: Strong bonding with the steel substrate, resistant to mechanical damage (e.g., scratches).

Cathodic Protection: Zinc acts as a sacrificial anode to protect the steel substrate.

Barrier Effect: Oxides of aluminum and magnesium (Al₂O₃, MgO) form a dense passive layer, blocking moisture and chloride penetration.

Salt Spray Test Performance:

Traditional Hot-Dip Galvanizing (HDG): Red rust appears after 500 hours.

Zinc-Aluminum-Magnesium (Zn-Al-Mg): No red rust after 1000-1500 hours (3-5x improvement).

Hardness: Higher coating hardness (~150-200 HV), resistant to wear.

Ductility: Suitable for stamping, bending, and other processes without coating peeling.

Outdoor/Harsh Environments: Service life of 15-20 years (compared to 5-8 years for traditional galvanizing).

Reduced Replacement Frequency: Ideal for long-term storage infrastructure investments.

Initial Cost: 10-20% higher than HDG, but lower lifecycle costs (less maintenance/replacement).

Lightweight Design: 10% lighter for the same strength, reducing transportation and installation costs.

Chromium-Free Treatment: Compliant with RoHS, REACH, and other international environmental standards.

Recyclability: Coating and steel substrate are 100% recyclable.

Cold Chain Logistics: Freezer warehouses (-30°C), seafood processing plants.

Coastal Areas: Port storage, offshore platform equipment.

Chemical Industry: Shelving or equipment supports in acidic/alkaline environments.

Automated Storage and Retrieval Systems (AS/RS): High-frequency access requiring long-term stability.

Narrow-Aisle Racking: Scenarios with stringent demands on upright strength.

Food and Pharmaceuticals: Chromium-free passivation for cleanliness requirements.

Automotive Manufacturing: Stamped parts, body structures (balancing corrosion resistance and lightweighting).

Q1: Are Zn-Al-Mg racks more durable than standard galvanized racks?

✅ Yes! The ZAM coating offers 3-5x better corrosion resistance, making it perfect for humid or salty conditions.

Q2: What’s the maximum load capacity?

✅ Depends on thickness—3.0mm uprights support up to 5,000kg per level. Custom high-capacity solutions available.

Q3: Can these racks handle freezing temperatures?

✅ Yes, they withstand -30°C, making them ideal for cold storage & freezer warehouses.

Q4: Do you offer custom sizes?

✅ Absolutely! We customize height, thickness, hole patterns, and more to fit your storage needs.

Q5: Are Zn-Al-Mg racks more expensive than standard racks?

✅ Initial cost is 10-20% higher, but longer lifespan & lower maintenance make them more cost-effective long-term.

Parameter | Specification |

Material | High-strength steel + zam coating |

Coating Thickness | 80-120g/m² (custom options available) |

Upright Thickness | 1.5mm / 2.0mm / 2.5mm / 3.0mm (customizable) |

Standard Height | 2m–12m (custom lengths available) |

Surface Treatment | Chromium-free passivation / anti-fingerprint coating (optional) |

Operating Temp. | -30°C to 80°C |

Zn-Al-Mg(ZAM) vs. Hot-Dip Galvanized (HDG) Steel: Key Differences & Advantages

| Feature | Zinc-Aluminum-Magnesium (Zn-Al-Mg) | Traditional Hot-Dip Galvanizing (HDG) |

|---|---|---|

| Corrosion Resistance | 1000-1500 hours salt spray (no rust) | 500 hours (red rust appears) |

| Self-Healing | Yes | No |

| Temperature Range | -30°C to 80°C | -20°C to 60°C |

| Surface Quality | Smooth, optional anti-fingerprint | Rough, requires post-treatment (e.g., painting) |

| Environmental Impact | Chromium-free | Contains hexavalent chromium (requires additional treatment) |

✔ Longer lifespan = Fewer replacements

✔ Lower maintenance = Reduced downtime & costs

✔ Superior corrosion resistance = Ideal for harsh environments

✔ Lighter yet stronger = Saves logistics & installation expenses